Custom Body Lift and Removal Kits

Designed and manufactured in

the USA by Visual Diagnostics LLC

Designed and manufactured in

the USA by Visual Diagnostics LLC

NOTE: Due to high order volume and supply chain issues, it may take some time for deliveries, production and shipments to catch up. Order backlog could be up to 8 weeks.

Contents:

- Introduction

- Vehicle Applications and pricing (a.k.a. )

-

Body Lift Kit - options

- Standard vs. Ultimate blocks, what's that all about?

- Standard vs. Heavy Duty hardware, what's that all about?

- What about manual transmissions and transfer case shifters?

- What about automatic transmissions?

- What about steering?

- Bumper relocation

- Radiator relocation

- Bed Spacers for pickup models

- Polyurethane Body Mount Bushings

- Body Mount Brackets

- What about wheel well liners or Gap Guards?

-

Frequently Asked Questions (and answers, too!)

<<< Please read this section

- If you are looking for a new body lift kit design <<< Please read this answer

- Lifts in General

- Body Mount Tech

- Materials

- Disclaimer

- Installation instructions

[ E-mail for additional product information or to place an order ]

NOTE: If you e-mail 4Crawler Offroad a question, . We get several e-mailed questions a week with invalid return addresses. We try to answer all e-mail questions in 24-48 hours, if you've sent a question and have not received a reply in that time, feel free to e-mail again (with a valid e-mail address to reply to). Also, if you utilize a Spam blocker, please be sure to allow a reply from the e-mail address "r.c.brown@ieee.org". Please consult the Frequently Asked Questions section prior to e-mailing a question and if you want to get an idea on kit pricing, see the pricing tables here. Your answer may already be there!Here is a plain e-mail link

Here is one you can cut and paste into the To: field of your e-mail program >>> sales@4Crawler.com <<<

Introduction:

So, why in the world did 4Crawler Offroad decide to make body lift kits? There were a few reasons:

-

When many folks want to do a "mild" 1" body lift, and

there was nothing commercially available.

- You either made your own or bought a 2" or 3" lift kit and cut it down to size

- Either option requires a fair amount of time and money

- Also, there are countless horror stories of improperly designed body lifts failing, such as drilling holes in hockey pucks, etc.

-

A few companies offer 1" body lift blocks:

- Rusty's Offroad, uses a cast block (not sure what metal is used), with holes that are too large for the stock Toyota hardware

- Another option is to buy a readily available 2" or 3" body lift kit, cut down the blocks and buy new, shorter hardware and the bracketry will be the wrong size

- It was apparent from the supplied components that it is doubtful anyone ever tried to actually install these kits on the target vehicle; bolts that are too long or too short, generic instructions, and general poor quality materials.

- Use "hockey pucks" or washers, or other spacers, which may not last long in this application

-

Finally, there are a number of "orphan" vehicles for which

there is little or no aftermarket support for due to low demand.

- If it has body-on-frame construction, it should be possible to make a body lift kit for it!

When it came time to upgrade a home-made 1" body lift, 4Crawler Offroad researched available materials and first decided to make a billet aluminum body lift block, similar in shape and size to the more common cast aluminum (at least that's what they claim they are made of) blocks, but out of stronger, solid material. The aluminum blocks were fine for a 1" lift, but a set of 3" tall blocks were made and installed, it just didn't look right. The 2" dia aluminum rod used was just not wide enough to offer support at 3" tall. While a larger diameter aluminum rod could have been used, it starts to get much more expensive and is harder to work.

After searching for a better material, Ultra High Molecular Weight (UHMW) polyethylene rod was selected and is available in a variety of sizes perfect body lift blocks. It has all the desirable properties one would want in a body lift block. Since this rod comes in long lengths, it can be cut any length desired from 1/2" up to 3" and anything in between. It takes a fairly significant investment in machinery and tooling to work this material. Also, since the parts are built to order, adapting them to other vehicles is not a large issue. After all, lifting a Toyota 4Runner 1" is fundamentally no different than lifting a Landcruiser or other vehicle 1". If it's got a body on frame construction and some way to get a spacer between the two, you've got a body lift.

At this point, you may be wondering what the heck a body lift is and why would you even want one...

[Return to the top of this page]Lifts in General:

So why a body lift and what other lift options are there? In general there are three basic techniques available to lift a vehicle:

- Install larger diameter wheels and/or tires

- Modify the suspension ride height

- Raise the body off the frame (assuming its not a unitized body construction)

Usually, installing larger tires (#1) require that either #2 or #3 be done to provide adequate clearance for the tires within the wheel wells. Suspension lifts (#2) can be simple or complex, depending on what is modified and how it is done. Similarly, body lifts (#3) can be simple or complex, but are generally simpler and less complex and expensive than suspension modifications. Since the body lift only raises the body, it has less adverse impact on the vehicles center of gravity than other lift techniques, since the frame, engine and drive train remain at the original location.

If you assume a typical vehicle with perhaps 25% of it's mass in the body and perhaps 10% in the axles/wheels/tires, then look at the various types of lifts:

- Taller tires will raise nearly 100% of the vehicle's mass higher at the rate of 1" for every 2" of increase in tire diameter, since essentially every part of the vehicle is raised. Thus a 2" taller tire (i.e. 1" of lift) will raise the vehicle's center of gravity 1".

- A suspension lift will raise about 90% of the vehicle's mass (all but the ~10% unsprung weight of the axles, wheel and tires) at a rate of 1" for every 1" of lift. Since 90% of the mass is being raised 1", the center of gravity will raise about 0.9" as a result.

- A body lift will raise only 25% of the mass of the vehicle (i.e. only the body) so a 1" body lift will only change the center of gravity of the vehicle by that same ratio, or 0.25".

- So, while all the above lifts will raise the center of gravity of the vehicle, they do so at different rates for the same amount of lift. And it is the overall impact of all the lift that a given vehicle has that will ultimately affect it's stability.

By raising the body up off the frame, you can gain needed room for larger tires and/or added ground clearance to protect the body from trail damage. However, a body lift will do nothing to change the operation of your suspension by itself. However, by combining a mild body lift, with a mild suspension lift may allow fitting a taller tire and result in a combined system that functions better than the individual components.

"Lift as much as needed, but as little as possible"

Each type of lift has its advantage and disadvantages. After all if there were just one perfect way to lift a vehicle, everyone would use that technique and you would have no other choices.

- Taller tires increase ground clearance under every part of the vehicle and work better off road as they give more traction and are able to tackle bigger obstacles. On the downside, taller tires often require regearing to make up for the lost torque due to the greater tire diameter. Likewise a taller tire needs more room to fit under the vehicle without rubbing. So you can either trim the body away to fit the tire or somehow lift the body away from the tires to make room for them.

- One way to make room between the body and tires is to raise the suspension. A suspension lift may offer better performance off road if it is capable of increased wheel travel and articulation. However, this is not always the case since some suspension lifts use stiffer, less flexible springs or blocks or drop brackets that do little to improve suspension capability, aside from the lift. On the down side, suspension lifts test to be expensive and the taller the lift the more the cost, since more issues arise that need to be addressed. Along with the lift, you may need longer shocks, longer brake lines, longer drive shafts, etc. Suspension geometry may be negatively impacted. And on some vehicles, there is an upper limit to high high a lift can be done. Also, suspension lifts may be advertised as X", but you may see more or less lift than advertised.

- This leads to the 3rd lift option of a body lift. Body lifts tend to be less expensive than suspension lifts. They are also more predictable in terms of lift height. After all you are placing a known thickness block between the frame and body and you will see exactly the amount of lift that the block is tall. So this makes a good alternative to getting that little extra lift you may find you need after installing a suspension lift, for example. A body lift will not affect drive shaft, shock absorber, or brake hose lengths. It will also not impact suspension or steering geometry. A body lift is a passive form of lift, in that it will not do anything to make your suspension work any better off road, aside from giving more room for the tires to move around under the body without making contact. Also there will be no increase in under vehicle ground clearance (a.k.a. break over angle), unless you also raise the drive train and other low hanging components up to match the lift. However, if bumpers are raised to match the body lift, you may see increase approach and departure angles.

See the following section for a list of frequently asked body lift related questions...

[Return to the top of this page]Here are some frequently asked questions:

- What constitutes a "mild" body lift?

- So, 1" isn't all that much, is it even worth doing?

- What about taller body lifts?

- Why might I need a body lift at all?

- I've got an XYZ vehicle, do you make a lift kit for it?

- What if I have a flatbed on my pickup and only need to lift the cab, do I have to buy a "full kit"?

- What is included in the body lift kit?

- How much does it cost?

- How long will it take to get the kit?

- How large a tire can I fit with X" of lift?

- What if I already have a body lift and want to remove it, reduce it's height or adapt it to another vehicle?

- I'm looking for an "RB" or "Roger Brown" body lift kit, where do I find that?

- What are bed spacers and do I need them?

- I already have a suspension lift and have some tire rubbing, can I add a body lift on top of the suspension lift?

- Is 4Crawler Offroad still in business and making body lift kits?

-

Does a body lift replace the body/cab mount bushings?

Have a question not listed above, send an e-mail and we'll try to answer it.

1. What constitutes a "mild" body lift?

- In our definition, this is any body lift you can install before encountering major modifications.

- With the stock Toyota design, there are two likely "mild" lift points, one at about 1/2" and another at 1".

-

At 1/2", you may be able to re-use the stock fasteners, taking

advantage of the excess bolt length, to get a little bit of lift.

-

This assumes you have at least 1/2" of exposed bolt length past

all the body mount nuts, check to be sure, this varies by year and body

style.

- If needed, 1/2" longer than stock hardware can be supplied.

- Useful for installing rock sliders - exposes a bit more frame for stronger attachment.

-

This assumes you have at least 1/2" of exposed bolt length past

all the body mount nuts, check to be sure, this varies by year and body

style.

- At 1", you'll need to replace the stock fasteners and possibly make minor modifications to a few other parts.

- Beyond 1", you'll start to have issues with more components like shift and steering linkages, gas tank filler hoses and other frame-body inter-connections, but on some vehicles, 1.5" or 2" lift is still pretty easy to do.

-

An automatic transmission has more complex linkages than a manual

transmission.

- Most Toyota automatic transmission linkages can accommodate a 1" body lift without adjustment and there is a bolt-on bracket for 2" and 3" body lifts on 1st and 2nd gen 4Runner and pickup. The 3rd gen 4Runner and Tacoma A/T linkage is fully adjustable, so no bracket is needed up to a 3" lift.

-

For the newer model Toyota vehicles with rack and pinion steering (like

'96 and newer 4Runners, Tacomas, etc.) anything over a 1/2" body

lift will likely require modification of the steering shaft.

- A bolt-on steering shaft extension is available.

- Note that certain localities may have their own definition of mild (i.e. allowed) body lifts. For example, in Hawaii, there seems to be a 2.5" body lift height limit, such that 2" lift is OK and 3" is not. So be sure to check your local vehicle regulations prior to ordering or installing a body lift. Other states may have overall lift height limits, or height limits on for example bumpers or headlights, etc. Here is an old page that had a decent summary (may be outdated by now):

2. So, 1" isn't all that much, is it even worth doing?

- One way to look at that, is that using a 2" taller tire (say going from 31" to 33") will raise your vehicle 1", granted all points of the vehicle will go up 1", including the body, but an inch is an inch.

- From a simple-minded perspective, using a 2" taller tire, will require 1" additional wheel well clearance (may need more) and a 1" body lift can provide that 1".

- Toyota trucks have fairly long front and rear overhangs, anything you can do to raise the ends of the vehicle will increase your approach and departure angles.

-

If you are planning to install body protection like nerf bars and

bumpers, then raising the body up and tucking the protection in

underneath will give you the protection and preserve the clearance

angles.

- Certain aftermarket bumpers are not possible to raise without major modifications. For example, the ARB pickup bumper is mounted in such a way as to make lifting it difficult. However, it is possible to leave it attached in the stock location.

- On vehicles with independent front suspensions, lift options are limited, so every little bit can help.

- For leaf springs, more arch in the spring, often implies a stiffer spring rate as well. For example if 4" of lift is needed for a given tire size, then a 3" spring and 1" body lift may give a better result than a stiffer 4" spring by itself. By spreading the lift over different components, the impact on any one component is lessened. For example a 4" spring lift may require drive shaft modifications, while a 3" lift may not. Its all a matter of degree and cost vs. benefit.

- A 1" body lift can make accessing parts on the engine like filters and the starter *so* much easier, this is an often overlooked side benefit of a body lift. Also, certain engine modifications like V6 headers, engine or transmission swaps require some body lift to be installed at all. An example is the popular 3.4L V6 engine swap in the earlier Toyota pickups and 4Runners. That generally requires a 1" - 2" body lit to fit the taller intake under the hood. Without a body lift, a hole must be cut into the hood to let the intake components fit.

- Removing and installing the transmission can also be easier since you have access to to the upper mounting bolts.

- Finally, you may find in certain states and/or countries, only a certain amount of lift is allowed on a given vehicle in order to pass inspection. While you might like to lift the rig 3", it'll only be legal at a 1" lift. Be sure to check your local vehicle regulations prior to installing any lift.

3. What about taller body lifts?

As you raise the body higher off the frame, you may run into more issues that need to be addressed. It is difficult to give a precise list of what issue will be encountered at an exact lift height, because there are some many variations in vehicles, when they were built, how they were built, etc. Some folks can thrown on a 2" body lift and have no issues at all. Others may run into issues at a 1" lift. Basically you can think of the relationship of lift height vs. potential issues you might encounter as a probability; the higher you lift the more likely you are to run into a particular issue. So, as mentioned elsewhere on this page; "Lift as much as needed, but as little as possible."

Best to consult the installation notes for your specific make/model/year vehicle to see what sort of issues that you may encounter.

- While a 1" body lift is considered mild, there are many folks running 2" and 3" body lifts. 3" is pretty much the maximum lift you should consider on the stock mounts. Above this and you should consider raising the mounting bracket on the frame to reduce the leverage caused by the taller blocks.

- At 2" on most Toyotas, you will find that in addition to the items that a 1" lift affects, you may need to extend the hydraulic line to the clutch slave cylinder and at 3" you'll likely need to extend it.

- At 1" the radiator shroud was probably OK as-is, but at 2", you should drop the radiator to re-center it on the fan.

- Same story on the shift levers, while modifications are optional at 1", they will probably need to be done at 2" and for sure at 3"

- You'll also need to let the steering shaft lengthen a bit and chances are the upper engine ground strap may need to be lengthened.

- With a 1st gen. 4Runner, a 2" lift allows you to raise the gas tank 2" using the existing pickup mounting holes on the cross member.

-

At 3", in addition to the above items need attention as well as

dealing with fuel lines at the gas tank. One option at the 3"

stage is to also lift the entire drive train by a similar amount.

- For example, the engine and transmission could be raised for additional break-over angle, the fuel tank could be raised, etc. This will restore many of the interference areas to their original position.

- This is what I chose to do on my 4Runner and you can find out more on that project here.

- Above 3" and you are asking for trouble and 4Crawler Offroad won't provide any components for that application. Best bet above 3" is to fabricate new body mount brackets raised up the desired amount and attach the body to the raised brackets without any lift blocks.

4. Why might I need a body lift at all?

- Lets assume you have installed a suspension lift in order to run larger tires. On level ground, you'll have lots of clearance between the tire and body. But, if your suspension has a decent amount of flex to it, when you bottom out the springs on the bump stops, what happens to the larger tire? Well, its now trying to fit into the same wheel well opening that was designed for the stock size tire and you may experience interference. So, by lifting the body up off the frame, you can gain clearance for larger tires to fit in off-road conditions. Other options are to trim the sheet metal around the wheel wells or run springs that are so stiff that they won't compress to the frame. Many people prefer a soft flexible spring with just enough lift to fit the tires, then a body lift to gain the clearance needed for off-road use.

- Body lifts are also commonly used with engine swaps and modifications like installing exhaust headers, etc. Lifting the body off the frame a bit gives a bit more room for larger engines, exhaust tubing or other components to fit. You may also find the increased clearance helps in routine maintenance tasks like working on starters, fuel filters, transmissions, etc.

5. I've got an XYZ vehicle, do you make a body lift kit for it?

-

XYZ is not any specific vehicle, replace XYZ

with Dodge, Jeep, Ford, Nissan, or whatever vehicle you have and are

interested in having a body lift kit designed for.

-

If it is not listed here, then

4Crawler Offroad doesn't have a design available for that application.

- But, everything listed on this page, outside the early Toyota 4Runner kits, has been designed with the help of people just like you that asked this very question.

-

If it is not listed here, then

4Crawler Offroad doesn't have a design available for that application.

-

If you

are willing to do the small amount of research needed to help 4Crawler

Offroad design and build the kit, chances are the answer will be YES!

-

First, verify that the vehicle uses a body-on-frame construction.

- Many modern vehicles use a uni-body or uni-frame construction where the body and frame end up being one piece.

- If there are no body mounts, bushings or bolts visible underneath, then chances are the body can't be raised off the frame with a body lift.

-

Then, you need to know how many body mounts the vehicle has

- And a rough idea of what size they are (i.e. 2" dia, 2.5" dia., etc.)

-

Then you will need to know what size the mounting hardware is:

-

Diameters and working lengths for each mounting bolt.

-

Be sure to measure the actual outer diameter of the threaded portion of

the bolt.

- On rare occasions, OEM bolts may have different diameters along the length of the bolt, either a shank (un-threaded part) that is larger or smaller in diameter than the actual threads.

-

Be sure to measure the actual outer diameter of the threaded portion of

the bolt.

-

Sometimes there is unused thread on bolts, so if you see more than

1/2" of exposed thread beyond any body mount nut, note that

information as it'll help size the replacement hardware properly.

- Bolts commonly come with only 1" of threaded length, but some OEM hardware is custom designed with 2" or more threaded length to account for the excess length, probably because of some automated manufacturing issue.

- Another way to think about this is if you were to cut the bolt off just past the tightened nut, how long would the remaining bolt be? That is the actual working length of the bolt.

-

Diameters and working lengths for each mounting bolt.

-

If items need relocating like bumpers, radiators, etc., we'll need to

know details on how they are mounted to the frame.

-

You'll need to supply information on the size of the mounting bolts and

the spacing of the holes:

- E.g. 2 - 12mm bolts, 60mm on center horizontally oriented - then we can design a bracket to raise that bumper to match the body lift.

-

You'll need to supply information on the size of the mounting bolts and

the spacing of the holes:

-

Getting this data won't be all that hard, get under your rig and count

the body mount locations. Find where all the bolts are, you should be

able to loosen and remove one at a time, pull it out, measure it and

put it back.

- Get dimensions, take pictures, and send them to 4Crawler Offroad.

- Bolt lengths are measured from the bottom of the head to the end of the shaft, DO NOT include the height of the head in the length. Also, some vehicles have, for example a 5" long bolt, but with 1" of thread exposed when installed, so, this should be noted, e.g. 'Bolt 5" long w/ 1" exposed thread'.

- Bolt diameters are measured at the shaft, its not the size of wrench that fits on the head.

- If a bolt goes into a captive nut inside the body, then the thread pitch (i.e. SAE, this will be Threads Per Inch, and if metric it'll be in mm/thread) will need to be measured.

- Don't assume all bolts are the same diameter or length. They are usually the same side to side, but can be vastly different sizes in different locations. And don't just measure down from the underside of the floor or guess, you really need to pull the bolt out, measure the length and best if you can send a photo of all the bolts side by side with a ruler for scale. If should be no problem to remove a body mount bolt, no vehicle support is needed, gravity will keep the body in place, just make sure you put them back before driving it!

-

So you provide 4Crawler Offroad with the specifications, you will get a

"custom" kit with no extra charge for the custom design work.

- 4Crawler Offroad will hope to make up the design cost in additional sales of kits for that application.

-

This also assumes that 4Crawler Offroad is able to source the required

hardware and other parts needed for the lift.

- For example certain sizes of metric hardware is difficult to find in lengths over 120mm long.

- This was recently done for the Kia Sportage and Sorento body lift kits. Within a few weeks of the initial contact, a kit had been designed, manufactured, and installed on the owners truck. A similar turnaround was seen for the 3rd and 4th generation Toyota 4Runners, the FJ Cruiser and the various other Landcruiser models.

-

A 3" body lift is the tallest that is safe and reasonable. Many

state/country vehicle codes may have 3" or even lower height

limits on body lifts, so be sure to check the regultions in your area

before ordering.

- If planning a body lift over 3", please consider cutting the brackets off the frame and raise them up the desired amount and weld them on with added bracing. The life you save may be your own!

-

Cost will depend on the quantity and size (outer diameter - OD) of the

blocks and hardware desired, here is some typical prices of some of the

items:

- 2" (50mm) OD Aluminum (aluminium) blocks run US$10.00/ea. up to 1"/25mm tall.

- 2" (50mm) OD UHMW blocks are US$5.00/ea. up to 1" (25mm) tall; add US$1.50/inch (25mm - or any fraction thereof) over 1" tall.

- 2-1/2" (64mm) OD UHMW blocks run US$7.00/ea. up to 1" (25mm) tall; add US$2.00/inch (25mm - or fraction thereof) over 1" tall.

- 3" (76mm) OD UHMW blocks run US$8.00/ea. up to 1" (25mm) tall; add US$3.00/inch (25mm - or fraction thereof) over 1" tall.

-

3-1/2" (90mm) OD UHMW blocks run US$10.00/ea. up to 1" (25mm)

tall; add US$4.00/inch (25mm - or fraction thereof) over 1" tall.

- Center holes are drilled by default, unless otherwise specified a hole to accommodate a 3/8" / 10mm bolt will be drilled.

-

If no hole or larger holes desired, specify with order.

- Add US$1.00/block for holes of 1/2" (12.5mm) or larger in diameter.

-

If you want to cut your own blocks for a custom application, bulk UHMW

rod is available as noted below:

- 2" OD UHMW rod priced at $20.00/ft.

- 2-1/2" OD UHMW rod priced at $33.00/ft.

- 3" OD OD UWHW rod priced at $38.00/ft.

- 3-1/2" OD UHMW rod priced at $50.00/ft.

- Longer bolts are available, cost varies with length, diameter and grade.

- Bed spacers for pickup lifts go between the bed and frame rails to provide overload support where the bed is not bolted to the frame. Most applications can use 0, 1 or 2 pair of bed spacers:

-

First, verify that the vehicle uses a body-on-frame construction.

6. What if I have a flatbed on my pickup and only need to lift the cab, do I have to buy a "full kit"?

- No problem, every kit is built to order. If you only need 6 blocks for the cab, that's what you order. If you've bobbed the bed on your pickup and only have 6 bed mounts instead of 8, that's what you order. If you only want 3/4" or 1.5" instead of 1" or 2", that's what you order. For example, an Ultimate lift kit for a pickup cab (only - bed replaced w/ a frame-mounted flatbed) would include 2-2" and 4-2.5" dia. blocks and 1/2 of a pickup hardware kit, since the flat bed is attached to the frame directly and probably won't be lifted. Contact 4Crawler Offroad for special pricing on these combinations.

7. What is included in the body lift kit?

- What is included in your kit depends on what you need. See above question for the case of a pickup cab only, no need to purchase the bed hardware. Each "kit" is built to order to meet your needs. See the pricing and options pages here for some common combinations. If the combination you need is not listed, don't worry, it is likely available.

-

Basically, you need:

- Blocks to raise the body off the frame

- Longer bolts and hardware to fasten the body back to the frame

- Assorted brackets, spacers, etc. to relocate items that cross the frame<->body interface

- Need some help designing your kit? I'm available by e-mail to discuss your particular needs.

8. How much does a body lift kit cost?

- Here are some common vehicles with kit pricing listed separately:

- Some other vehicle kit options are listed elsewhere on this web page

9. How long will it take to get the kit?

-

4Crawler Offroad tries to stock most of the common parts for the

various lift kits (nuts, bolts, etc.) Other parts are hand

crafted as needed to fill your exact order. Think of the

popular fast food place, your hamburger is made to order while you

wait, "Have It Your Way". For us, this can take 1

- 2 weeks, depending on backlog (as noted below).

- So what is a backlog? Well that means the time it will take before we can get to or start working on your kit order. Then once we start working on it, then it'll take the time noted above to finish it. It is hard to be more specific, since every order is unique, including your order and all the orders in the queue before yours that we need to finish first. And since every order is unique, it can take a variable amount of time to finish and when those unique orders are submitted in a random order and all have their own special requirements, trying to predict fabrication times to the day for any given order is impossible. So the above estimates are typical, meaning that some orders may take that amount of time, some a little less and some a little more.

- Realize that we are not just sitting here waiting for your order to arrive, so there are likely quite a few orders ahead of yours in the queue. It may take less time for simple orders and up to a week more for complex kits. So don't place an order a couple of days before you have time scheduled for a shop to install your kit.

- And while it would be nice if we had a huge warehouse full of every single component we make that we could just pick from to fill your order, we don't. In fact, companies that have huge warehouses full of inventory, usually only stock a limited selection of top sellers. In fact they will usually drop items that don't sell because it costs too much capital to produce and store the inventory on slow moving items. We can't hope to compete with those "big box" shops on either price or volume, so we don't even try. The reason you likely have some to us is that nobody else makes what you are looking for. We can "afford" to have items we might only sell a few of a year, since if nobody orders that item, it costs us very little as we don't manufacture the item until it is ordered. One way to be able to stay in busines making relatively low volume products is to make a variety of different items. So when we produce items, instead of making one X then one Y then one Z then another X, etc., we instead try to group up similar orders and make up similar components of those orders at the same time, so we would make 2X's, then Y then Z. It is more efficient in terms of machine setup, etc. to do this, so we can keep out costs down. But it can result in a delay in you getting your order. If you happen to order the day after we just finished a run of the item you ordered, it may be a week or two before we get back to making that exact part. Also, if your order includes 10 different items, it is going to take longer to fill your order than it if for another order that may only need 2 different items. And some items we do make in larger volumes, so if you happen to order when we have some of that item in stock, you may get it right away, but if we are out, then it will take some time to make another batch of that item. So this is a case where making many of a part may be faster or it may be slower, just depends on what we have in stock the day you order. So when you ask us "how long will it take?", we really can't give an exact time, we'll probably send you a link to this section of the web page.

- Parts are shipped via US Mail by default. Delivery time depends on shipping distance and method, Priority Mail is the default shipping method, 2-3 day typical delivery time in the US and 6-10 days for international delivery. Parts may also be picked up in the SF Bay Area of California if you prefer.

-

How will I know my order has been received?

- An acknowledgement will be sent by e-mail when your order is received. If the order was placed via Paypal, you'll see the transaction status change to "In Process" once the order is received or "On Hold" if further information is required. Note that "In Process" indicates that the kit is IN the PROCESS of being fabricated to your specifications. Unfortunately, due to some changes made in the Paypal order system, this feature is not working at the current time. If you don't receive an e-mail confirmation from us, it might be your order was one that we did not get notified about, so feel free to send us a copy of your order confirmation so that we can look it up in our on-line system.

-

How will I know when my order has been

shipped?

- A package tracking number will be e-mailed to you, if applicable, when the parts ship. Again, on Paypal orders, a shipping status e-mail will be sent from Paypal with any applicable tracking information and likewise, the transaction status page will show the same information and your package will generally be shipped the same day you get the shipping notification e-mail. Note on orders shipped via US Mail, the tracking number may not update as frequently as with other carriers. This is because the tracking number is only guaranteed to be scanned upon delivery of the package. You may be able to get more accurate tracking information by taking the tracking number to the Post Office and have them look up the status on their internal system. And just like the hamburger place, 4Crawler Offroad does not keep stacks of orders sitting around that are ready to ship. When your order is complete, it is boxed, labeled and dropped off at the shipper typically on the same day.

-

What if something is wrong with my kit when

I receive it?

- If the package was damaged in shipment and some parts fell out or if you think you received incorrect parts or are missing parts, please be prepared to provide photographic documentation of the contents of the package. Contact 4Crawler Offroad via e-mail and state the nature of the problem and attach any images you have. If parts are missing or damaged, 4Crawler Offroad will attempt to send out replacements in a timely manner and also file a claim with the shipper on insured shipments. You must of course request insured shipping if you wish to have that coverage. If parts of of an incorrect size or application, please let us know and we'll try to work out the issue. The only way that 4Crawler Offroad will know about these sorts of issues is to get feedback. And it is not unheard of to run into a vehicle with odd-sized hardware, probably happens every few years. We'll ship hardware exactly like we have used on many dozens to hundreds of similar vehicles only to find out on one particular vehicle that the mfg. changed the size.

-

Can I return lift kit components I don't

use?

- Yes, any lift component can be returned, in unused condition, for exchange or refund (less a restocking fee) if not needed for the lift:

NOTE: Due to high order volume and supply chain issues, it may take some time for deliveries, production and shipments to catch up. Order backlog could be up to 8 weeks.

10. How large a tire can I fit with X" of lift?

- There is no way to provide an exact answer to this question, at least in general. There are so many variables, the actual diameter and width of the tire, the profile of the tread, the size and offset of the wheel, the suspension mods on the vehicle, your willingness to make minor of major mods to the body (fender trimming) all come into play.

-

The best bet is to locate a lift vs. tire size chart for your vehicle

and see if that helps. For example, if you have a Toyota Tacoma, then

the Tacoma Territory Tire and Lift FAQ section

should have your answer.

- If that file is not available, an alternate version is available here...

-

If you have a vehicle that is similar to another, for example the 3rd

gen 4Runner and the Tacoma are very close in design, so the above lift

vs. tire size chart should be pretty close. Or the FJ Cruiser and 4th

gen. 4Runner are almost identical to each other, so expand your seach

to similar vehicles.

-

Find a vehicle specific forum and ask other owners what they are

running, lift-wise for a given tire size.

- There are lots of on-line forums where it should be easy to find someone with a similar setup to what you want to do.

- There is a good write-up on the inner fender trimming process (aka Pinch Weld Mod) about half way down this web page.

-

Find a vehicle specific forum and ask other owners what they are

running, lift-wise for a given tire size.

- Short of a vehicle specific forum, you can try measuring. A body lift will raise the body up and most tire fitment issues are with the front wheels, because of the steering. See if you can find the worst case suspension/steering combination and then carefully measure clearance around the current tire and allow for the larger tire. For example, assume you want to go from a 31x10.50 to a 33x12.50 tire on the same rim. The new tire will therefore be 1" wider on the inside of the wheel, 1" wider on the outside and will extend 1" farther out from the wheel. So, if you had a 1" square block and could run that around the face of the tread and sidewalls all they way around the wheel well without hitting anything, chances are that tire would fit. If it does hit something like the fender, would raising it, say 1", make any difference? If it hits some part of the steering or suspension, then a body lift won't help.

-

Another way to measure would be to use a bumper jack to lift one or

both ends of the vehicle up the desired lift height and then do your

measuring with that simulated body lift. This is fairly safe to do, you

are not actually lifting the tires off the ground, just taking a little

weight off the vehicle and letting the body rise up an inch or two to

simulate where it would be with a similar amount of body lift. That way

you can see exactly how it will look and measure to the "pinch

points" where rubbing might occur. And you can try and correlate

clearances measured raised and lowered to see what affect various lift

heights will give you.

- On some of the later model Toyota vehicles, you may find that the A-pillar body mount bracket is a limiting factor on tire size. You can raise the body with a body lift to let that clear the tire, but the body mount bracket itself is attached to the frame. It will stay there after a body lift. You can find write-ups on-line on how that bracket can be modified for additopnal tire clearace.

-

For the IFS Toyota pickups/4WD and 4Runners/2WD/4WD ('86-'95) the

following tire/lift combinations apply (note 2WD pickups sit a few

inches lower and thus need more lift to fit the same size tire as a

4WD):

- 31x10.50 will fit fine, no mods

- 32x11.50 should fit, may require minor adjustments

- 33x9.50/10.50 may fit w/ no lift on stock wheels w/ minor fender trimming and torsion bar adjustment

- 33x12.50 on 15x8/4.75" backspace wheels needs 1" body lift, and front torsion bar lift (1"-2") or 1.5" ball joint spacer and some sort of rear suspension lift (such as longer spring shackles or a coil spring spacer) to level the truck, plus some fender trimming. Here is a picture of this combination showing the minor front fender trimming needed to fit the tires. Conventional wisdom suggests a full 4" IFS lift for this wheel/tire combination, but using a combination of milder lift components will produce the same end result that will function as well if not better than the taller all-in-one lift kit and at less cost. And in case you think this won't work, take a look at this very combination in action in 4x4Wire's Hot Toys write-up on Don West's '94 pickup.

- 35x12.50 on 15x8 w/ 3.75" backspace wheels needs 4" IFS suspension lift plus 2" body lift for good fit. Many IFS lifts require less backspacing on the wheels to clear the dropped A-arms, this in turn pushes the wheels/tires out farther from the body, making tire/body contact more of an issue. The 2" body lift can help reduce rubbing. Less lift may be possible with more fender trimming.

-

With all lifts, whether body or suspension: "Lift as

much as needed, but as little as possible"

- What this means is that for best results add as much lift as needed to meet your needs but no more. If 1" of lift is enough for your application, going to 2" or 3" is just extra cost, more installation issues you may encounter, etc.

-

So, I want to do a mild lift, which type of lift do I choose,

suspension or body?

- Ideally, you would want to get the suspension set up first. Why? Because suspension lifts are the most variable in terms of how much lift you will get. That is you may get more or less lift than the kit was "advertised" to provide. Nothing wrong with this, it is just life. Your vehicle may be lighter or heavier than what the kit was designed for. Also, things like springs settle over time. Also suspension lifts vary in flexibility, so your new suspension may or may not allow the wheels to compress up as much as stock.

- All this said, if after setting up the suspension to your liking and installing the desired size tires, and you find out you get some tire rubbing, then is the time to size up the body lift. When you can see how much tire rubbing you are getting, you can decide if some inner fender trimming is all that is needed, or if raising the body up vertically 1", 2", etc. is what is needed.

-

And a lift is not always the answer. This just goes to show you need to

identify the cause of the tire rub:

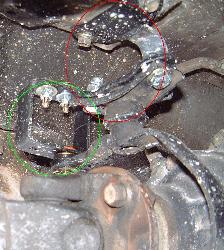

- In the case of the Toyota FJ Cruiser and 4th generation 4Runners, the most likely cause of tire rubbing is due to an oversize body mount bracket behind the front wheel well. This is a case where a body lift will have absolutely zero affect on the tire running as that bracket is part of the frame that the body rests on. So short of a suspension lift to move the tires far below the frame, modifying the body mount bracket is the way to go: Body Mount Chop How-To...

11. What if I already have a body lift and want to remove it, reduce it's height or adapt it to another vehicle?

- 4Crawler Offroad is happy to work with you to do this. We can offer kits to replace the body mount hardware to restore the vehicle to stock height. We can also supply lower height lift blocks in almost any combination and can also supply components needed to adapt a lift kit for one vehicle to another. Just drop us a line and we'll be happy to help you with your project.

-

If you have a vehicle with an already installed body lift and you want

to remove it, for many vehicles

listed below, simply order the typical 0" kit

to get a set of stock height hardware to allow for a body lift to be

removed.

- Or you can simply measure the length of the bolts you are removing and then subtract the height of the lift blocks you are removing to come up with the length of bolts needed to replace the extra long lift bolts.

- With this information, you can visit a local hardware store and purchase hardware of suitable dimension to replace what's there. Another option is to visit your local dealer parts counter and they can often supply stock hardware. So you don't need to purchase our removal kit if you want to do it yourself.

- And removal is the reverse process of installation. In short, you'll need to remove all the relocation brackets that were installed with the lift. These may include the bumpers, radiator, steering shaft, gas tank filler hoses, etc. Then you'll remove the body lift blocks and longer bolts, lower the body down and the replace those bolts with the stock length bolts (kit D as mentioned above).

-

One question that always comes up when removing a body lift is what

about the body mount bushings? One common misconception is that a body

lift replaces the body mount bushings with the body lift blocks. Except

in a few cases where the body lift is done via taller body mount

bushings, you generally leave the body mount bushings in place and then

add the body lift blocks between the body mount bushing and the body, as noted in this section of this web page.

- Now that is not to say that you might want to replace the body mount bushings along with removing the body lift. Inspect your body mount bushings and see if they are worn out or damaged. With the older factory rubber body mount bushings, time and the added wear and tear of the body lift blocks (especially the undersized blocks commonly used in the various after market kits out there), those bushings may be ready for replacement. Simply add kit P to your parts order and get a new set of poly urethane body mount bushings to swap out for the worn out rubber parts. And there is no better time to do this, as you'll have perfect access to the body mount bushings when you remove the body lift.

12. I'm looking for an "RB" or "Roger Brown" body lift kit, where do I find that?

- 4Crawler Offroad is the name of the company that was created and is owned by Roger Brown. So some people mistakenly call the kits "RB" or "Roger Brown" body lift kits. 4Crawler Offroad would like to encourage everyone to use the official company name when referring to these products to help avoid confusion and for legal reasons as well. It would be the same as walking into your local computer store and asking for a copy of "Bill Gates Word" or "Larry Ellison Database" software. Hopefully you would get what you were looking for, but you may not. So, to answer the Frequently Asked Question "Where can I find an RB body lift kit?" The answer is there is no such a thing.

13. What are bed spacers and do I need them?

-

In many vehicles, the bed of the vehicle rests on the frame without

being physically connected, as at a real body or bed mount bracket.

This typically happens under the rear wheel well, where it would be

difficult to add a support bracket to the frame to attach the bed to.

Instead, the bed rail (on both pickups and also on many full-bodied

vehicles like 4Runners) simply rests on the frame rail. In cases where

the bed is heavily loaded and tries to sag, that point of contact will

support the load in the bed without it bending in the middle. This is

mainly useful if you carry heavy, unsupported loads, such as sand,

gravel, sod, etc. If you instead carry loads like a motorcycle, lumber

or other cargo capable of supporting itself in the middle, then the bed

is less likely to sag. When a body lift is installed and the bed is

raised above the frame, this contact point no longer is effective. This

a "bed spacer" can be attached to the frame to provide a

raised point of contact for the bed. So the questions that come up with

bed spacers are do you "need" them and how many do you need?

- Need is determined by how you use your vehicle, specifically for cargo carrying. If the most you put in your vehicle's bed is a cooler and pair of folding chairs, then you probably don't need the spacers, at least to support the bed. If you haul heavy, bulk cargo, then yes, you do need them. And as to how many? Look at your vehicle, locate and count the number of places the bed rests on the frame. Typically there is just one contact point on each side in the rear wheel well, you one pair of spacers is what you need. Some pickups, have to sets of contact points, but they are nearly at the same place. So you could get by with one pair or put spacers at both pair of locations. It is all up to you and what you want your body lift to encompass.

14. I already have a suspension lift and have some tire rubbing, can I add a body lift on top of the suspension lift?

-

Sure, there are generally no issues combining the two. A suspension

lift raises the frame above the axles. A body lift raises the body

above the frame.

- If you consider the two lifts, you could imagine supporting the frame on jack stands and removing the front and rear axles, the body would not "know" the difference. This would be an "infinite" suspension lift, not very practical, but just to illustrate the point. Likewise, imagine removing the body entirely from the frame and moving it some place else. This would be an "infinite" body lift, again not practical, but illustrates the point that the frame, suspension and axles could "care less" that the body is not present. Practical suspension and body lifts leave their respective parts connected and just provide a reasonable amount of lift.

- So, within reason, a suspension lift and a body lift can be installed on the same vehicle. This is often a good combination, letting a mild suspension lift be combined with a mild body lift to allow a larger size tire to be fitted without rubbing than could be fit with one or the other lift alone. Likewise, the cost of say a 2" suspension and 2" body lift may by much less than to buy a full 4" lift kit with complex brackets, etc.

- And, if you need for example 4" of total lift to fit a given size tire, you can generally add the combined height of the suspension and body lift to get to this total lift height. So if you had say a 2.5" suspension lift, you could add a 1.5" body lift to reach that desired 4" total lift height.

15. Is 4Crawler Offroad still in business and making body lift kits?

- Yes!

16. Does a body lift replace the original body/cab mount bushings?

- Generally no. Our body lift blocks are designed to sit on top of the body or cab mount bushings. These bushings help to isolate the body/cab from road vibration and also allow the frame to twist and flex below the more rigid body. This applies in reverse as well, if removing a body lift, you generally just remove the lift blocks and set the body back down on the original body mount bushings. That said, you can replace the OEM rubber body or cab mount bushings with polyurethane material. There is at least one company that offers a replacement poly bushing kit that incorporates a mild body lift by using taller than stock body mount bushings. We chose the separate lift block approach because it gives the customer the option of changing the body lift height or removing it and going back to stock height. Also this allows us to offer custom body lift heights without the significant expense of designing and producing custom polyurethane bushing molds.

[Return to the top of this page]

Body Mount Tech:

Body mounts are what connect your trucks frame to the cab and/or bed. For strength, pickup beds are typically bolted directly to the frame, while the cab is mounted with compliant bushings (usually rubber or polyurethane) to isolate the cab from road noise and vibration. Starting at the front, there are two mounts behind the bumper, two more are located at the front foot well, two more behind the front seats. Then, in the 4Runner, there are two more in the rear passenger seat well, and two more at the rear of the cargo area. The pickup has 8 mounts on the bed (4 on each side), two near the front of the bed and two near the rear. You should try to locate each mounting point, and be sure you can gain access to both the top and bottom of each mounting bolt before undertaking a body lift.

The body/bed are connected to the frame by the mounts, as described above, to brackets (or horns) attached to the frame. In a body lift, spacers are installed between the body and the mounting brackets or bushings to lift the body above the frame.

From the factory, you'll find rubber body mount bushings. Over time, the rubber cracks and weakens with age. This can lead to what is called "shudder", which is a sort of side-to-side shaking felt when hitting bumps on the road. I tried everything to correct this problem on both my Toyota Landcruiser ('74 FJ-55) and later on my '85 4Runner, but nothing seemed to help until I installed polyurethane body mount bushings. It seems counter intuitive, that putting on a stiffer, less compressible bushing material would actually reduce this vibration, but that's what seems to happen. I think the vibration is actually caused by the relative motion allowed by the softer rubber. In technical terms, the resonant frequency is proportional to the stiffness of the compliant member. The rubber is soft and very compliant, leading transmission of the low frequency shudder, that is within the frequency range of bumps transmitted up from the road. The stiffer polyurethane (approx. 92A durometer), shifts the resonant frequency up to a higher value, which is effectively absorbed by the suspension of the vehicle.

All this leads to the point that if you are going to the trouble of installing a body lift, why not also put in some new polyurethane bushings, too. They will make a dramatic improvement in the ride quality of your vehicle if your old rubber bushings are damaged or worn out. If done in conjunction with a body lift installation, there is minimal extra work required. If you don't change out the stock bushings, the added leverage of the lift blocks may contribute to a worsened ride quality. A couple of polyurethane bushing manufacturers are:

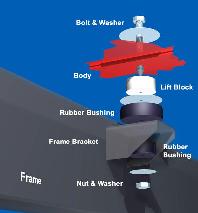

4Crawler Offroad carries both of these brands for various applications. Typically, body mount bushing kits often include no instructions and even if they do, make no mention of body lift blocks. See the schematic diagram, below, for a simplified cross section of a properly installed body lift and bushing together. Note that not all vehicles will have all the parts below, for example, washers may or may not be present, bushings may be two-piece (as pictured) or one-piece:

- Color Code:

-

Part supplied in body lift kit

- Part supplied in poly bushing kit

- Original or existing part

- Part supplied in poly bushing kit

XX New longer bolt

---- Factory Washer, either tabbed or round

~===========~ Floor of the cab or bed

+----+

| | Body Lift Block, if applicable

| |

+----+

-------- New washer (if supplied w/ poly bushing kit)

+------+

| | Larger poly bushing (Body or cab only)

+------+

========== Bracket off of the frame

+----+

| | Smaller poly bushing (Body or cab only)

\--/

---- Factory or HD washer

XX New lock nut

If re-using the stock body mount bushings, the picture is a little different:

XX New longer bolt

---- Factory Washer, either tabbed or round

~===========~ Floor of the cab or bed

+----+

| | Body Lift Block

| |

+----+

-------- Factory top washer (may be bonded to body mount bushing)

+------+

| | Upper factory rubber bushing (Body or cab only)

+------+

========== Bracket off of the frame

+----+

| | Lower factory rubber bushing (Body or cab only)

\--/

-------- Bottom factory washer(may be bonded to body mount bushing)

XX New lock nut

There is a metal bushing that goes inside the poly bushings, it gets sandwiched between the two washers outside the poly bushings and keeps them from getting compressed too much. When you tighten down the bolts, you bottom out this internal bushing. Note that not all vehicles will have all the parts below, for example, washers may or may not be present, bushings may be two-piece (as pictured below) or one-piece. You can think of the body mount bushing like an Oreo-type cookie. The top and bottom washers are like the cookie wafers and the rubber part is like the creme filling. Without the sleeve in between the washers, the filling (i.e. rubber bushing) would squeeze out when you tightened the body mount bolt. Since the body lift blocks are not compressible, they do not need a sleeve or top/bottom washers to work. Rather they just get clamped in between the top washer of the body mount bushing and the floor of the cab/body. The clamping force of the body mount holds the block in place.

The following image is an excellent rendering of a typical body mount, courtesy of John Evaskovich:

One concern with body lift blocks is possible electrolytic corrosion due to dissimilar metals touching. This can be a problem with aluminum blocks and the steel of the body. If you wish, you could apply a heavy paint or spray-on undercoating to the top of the blocks. Anotehr option would be to cut out some plastic washers from an old plastic milk jug and use that to separate the aluminum and steel if desired to prevent possible electrolytic action. The big advantage of the UHMW polyethylene body lift blocks is that they eliminate this possible problem, as polyethylene is inert and self-lubricating, so you won't even have problems with the paint wearing off the steel and causing rust as is common with extruded fiberglass blocks.

[Return to the top of this page]Body Lift Kits:

What exactly is in a body lift kit?

- Something to put between the frame and the body (lift blocks)

- Longer-than-stock bolts to hold the body to the frame (mounting hardware)

-

Various brackets to relocate items that connect between the frame and

body, such as:

- Bumpers, front and rear

- Steering Shaft

- Radiator

- Shift Linkage

So, which vehicles do these kits fit?

What is listed below is information on all the vehicles we have sufficient information to construct a body lift kit or components for. If what you need is not listed below that means we do not have sufficient information required to design and build that component or vehicle kit. If you would like us to design any not-listed components or kits, see this section of the web page for the required information. Almost every kit listed below has been designed from information supplied by customers just like you.

All our body lift kits are proudly designed and manufactured in the USA

-

Toyota:

- 1979-1995 2WD/4WD Pickup/Hilux/Trekker and T-100 (click here for pricing and options)

- 1984-current 2WD/4WD 4Runner/Hilux Surf and Lexus LX-450/60/70 models (click here for pricing and options)

- 2WD/4WD Tacoma, Tundra and Sequoia (click here for pricing and options)

-

Landcruiser (click here

for models, pricing and options):

- Including: FJ-40, 45, FJ-55, {F,B,H}J-6{0,1,2}, FJ-70, FJ-80 (and Lexus LX-450) and, FJ Cruiser

- Mitsubishi

- Kia

-

Isuzu:

-

Amigo - Tony Vang has a nice

2" lifted '99 Amigo

- Uses 8 - 2.5" OD blocks, cost: 1" - $56.00, 2" - $72.00, 3" - $88.00

- This is a block-only kit at this time, for a more complete lift kit, provide the information requested here...

-

Rodeo - 1/2" and 1" lift kits

- 2WD uses 10 - 2" OD blocks (cost $60.00)

-

4WD uses 10 - 2" OD and 2 2.5" OD blocks (cost $74.00)

-

For the 1" / 4WD lift, 4 hardware options:

- Supply your own

- 6 longer metric bolts for the rear, cost $36.00

- 6 longer metric rear and 6 longer SAE bolts for the front, cost $66.00

- 12 longer metric bolts for all body mounts, cost $72.00

- 1/2" lift can re-use stock hardware

-

For the 1" / 4WD lift, 4 hardware options:

-

Taller lift blocks (only) (1.5", 2" and 3") are

available for special order

- Add $15.00 per extra inch (or fraction) of height for 2WD kits and $19.00 for 4WD kits

- Should also fit Honda Passport models

-

Trooper:

-

Uses 4-2.5" and 8-3" dia. lift blocks typically

- Blocks: up to 1": $92.00, up to 2": $124.00

- Hardware, mix of 6 metric (M10) and 6 SAE (3/8") bolts $65.00, all 12 bolts in metric (M10) $80.00

-

Uses 4-2.5" and 8-3" dia. lift blocks typically

- Note that these are not complete kits, for other hardware/brackets, see this section of the web page.

-

Amigo - Tony Vang has a nice

2" lifted '99 Amigo

-

Nissan

-

Frontier pickup

-

Uses 4-6 2" OD blocks (bed) and 6-8 2.5" OD blocks (cab)

(total of 12-14 typically) and 1-2 pair of bed spacers

- 2" blocks drilled for 10mm bolt and 2.5" blocks drilled for 12mm bolt

- 2" OD blocks/ea.: $5.00/1", $6.50/2", $8.00/3"

- 2.5" OD blocks/ea.: $7.00/1", $9.00/2", $11.00/3"

- Metric hardware now available, $65.00 for the 8 - 12mm and 4 - 10mm on the double cab models

- Order Bed Spacers

-

For a typical double cab model, typical kit of ultimate blocks

(4-2"OD, 8-2.5"OD) + hardware + 2 pr. bed spcrs, cost:

- 1" - US$161.00 + applicable sales tax and shipping

- 2" - US$187.00 + applicable sales tax and shipping

-

Note that there is some variation in the bolt

lengths for the Nissan Frontier pickup models.

- So to ensure best hardware kit fit, you may want to send us the measurements of the bolt lengths and diameters for your particular vehicle so we can verify problem bolt lengths for the body lift kit.

-

Typically all cab bolts are 12mm dia. and all the same length, 8 in

total

- If you have 2 or more longer bolts, then add $25.00 to the hardware kit price for those longer bolts.

- Bed bolts are 10mm in dia. and all the same length, 6 in total.

- If it's easier, we can send the default hardware and then if needed work with you to exchange needed bolts afterwards.

- Note that these are not complete kits, for other hardware/brackets, see this section of the web page.

-

Uses 4-6 2" OD blocks (bed) and 6-8 2.5" OD blocks (cab)

(total of 12-14 typically) and 1-2 pair of bed spacers

-

Frontier pickup

-

Note that the applications below are body lift blocks only

- For other hardware/brackets, see this section of the web page and let us know what you'll be needing...

- Don't order the lift blocks and then complain that you didn't get bolts or other brackets!

-

IH Scout

-

80 and 800 series, 9 - 2" OD blocks, 7/16" center hole

- 1" - $45.00, 2" - 58.50, 3" - $72.00

-

80 and 800 series, 9 - 2" OD blocks, 7/16" center hole

-

Other vehicles - Information on custom applications

-

Jeep CJ, TJ, XJ (SWB) use 10 - 2" OD blocks,

- $50.00 - up to 1", $65.00 - up to 2", $80.00 up to 3"

-

Range Rover uses 10 - 2" OD blocks w/ 10mm

holes,

- $50.00 - up to 1", $65.00 - up to 2", $80.00 up to 3"

-

early Ford Bronco uses 8 - 2.5" OD blocks,

- $48.00 - up to 1", $64.00 - up to 2", $80.00 - up to 3"

-

Chevy S10 Blazer uses 10 or 12 - 2.5" OD blocks w/ 12mm holes:

- 10 mounts: $60.00 - up to 1", $80.00 - up to 2", $100.00 - up to 3"

- 12 mounts: $72.00 - up to 1", $96.00 - up to 2", $120.00 - up to 3"

-

Jeep CJ, TJ, XJ (SWB) use 10 - 2" OD blocks,

Below are some examples about what kind of options are available:

|

|

| Aluminum Lift Blocks | UHMW-PE Lift Blocks |

|

|

| Toyota 4Runner Kit | Toyota Pickup Kit |

|

|

| Toyota {F,B,H}J-6{0,1,2} Landcruiser | Kia Sportage |

|

|

| Pickup/Tacoma Bed Spacers | Steering Shaft Extension |

-

Body lift blocks

-

1/2" - 3" lift w/ or w/o hardware:

-

A lathe is used to drill the bolt hole in the center of the block

- A close fit is an important design feature as it keeps the body from shifting around on the frame, taller lift blocks have slightly larger holes drilled to ease installation of the longer bolts.

- Cast blocks often have oversized, irregularly shaped holes due to the nature of the mfg. process

- On UHMW blocks taller than 1", you may notice a slight deviation of the hole from the center of the block due to variations in the block diameter in the extrusion process. Since the blocks are slightly oversized in most applications, the slight offset from center has no affect on the function of the block.

- The one face of the block is than machined square to the axis of the center hole

- Then the opposite face is machined square and the edges are slightly chamfered to reduce stress concentrations

-

A lathe is used to drill the bolt hole in the center of the block

-

Lift block options:

-

2" dia. billet Aluminum

Blocks

- Cost is $9.00/ea for the 1" tall blocks; taller blocks not available.

-

UHMW Poly

Ethylene blocks

- Available in 2", 2.5", 3" 3.5" nominal diameter blocks.

- UHMW is a dense plastic, that will eliminate possible corrosion and squeaking problems that could potentially happen with a metallic block.

-

UHMW blocks are available in two sizes:

-

Standard body lift:

- All 2" dia. blocks

-

Ultimate body lift:

- Combination of 2" dia. for front and bed mounts, and 2.5" dia. for remaining cab mounts:

- The Ultimate blocks are the same diameter as the larger cab/body mounts so offer the ultimate in strength, both in the block itself as well as spreading the load of the body over the sheet metal contact point.

-

Custom height lift blocks are

available as well:

-

Any size lift from 1/4" to 3", no-cost consultation on your

custom applications

- Specify center bolt hole size for drilling

- A 1/2 " body lift is an interesting proposition, as many stock mounting bolts have approx. 1/2" of excess length, so this height lift, while not a lot, can be done without the added expense of replacing the stock bolts. If interested in this option, 4Crawler Offroad can make 1/2" blocks, drilled for the 10mm stock bolts

-

Any size lift from 1/4" to 3", no-cost consultation on your

custom applications

-

Standard body lift:

-

A new product addition is a 1-3/8" body lift block for the Kia

Sportage. This block has a number of important features:

- It is 3.5" in diameter with an integral "cup" to contain the rubber body mount bushing as well as a tapered end that fits into the "cup" on the underside of the body.

- It has a 19mm center hole to accommodate the factory body mounts bolts and is the tallest lift possible with the existing hardware, a total of 8 are required.

-

2" dia. billet Aluminum

Blocks

-

Longer bolts and nylon lock nuts:

- The stock bolts will not work beyond about 1/2" of lift on most vehicles

-

Several hardware options are

available:

- Standard, heavy duty, stainless steel and metric.

- Standard bolts have approx. the same strength as the factory hardware and will fit the stock body washers without modification

- Heavy duty bolts are about 25% stronger than stock and will fit into the stock mounting holes and body washers with some slight modifications.

- Stainless steel hardware is rust resistant.

- Metric hardware is just that, same diameter and grade as stock, although thread pitch and head size may differ from stock. While we try to get metric in a zinc plated finish, sometimes we can only source a particular length and thread pitch in black oxide finish. For these bolts, you can either oil them periodically (that's how they are intended to be used), or you can clean and paint them prior to installing.

- The pickup bed bolts (or nuts) include tabs (like stock, where applicable) for ease of installation.

-

Hardware is SAE Grade 5 or better, which combines good tensile as well

as shear strength.

- Hardware is either zinc or cadmium plated for corrosion resistance

-

You may also supply your own mounting hardware

- If you want to use custom size bolts, blocks can be drilled to your specifications or even supplied un-drilled

-

Radiator drop brackets (if needed):

-

The radiator (and fan shroud) are attached to the body, the engine (and

fan) to the frame

- Fits standard 20cm Toyota radiator bolt spacing, drilled for 1" and 2" drop

-

You may be able to simply remove the lower radiator shroud extension

-

With a 1" lift, you will have to modify the radiator flange a bit

to install the bracket

- Please refer to the installation instructions for details

- An electric radiator fan eliminates this problem as the fan is attached to the radiator and not the engine

- Tacoma trucks do not require a bracket and it is possible to simply use existing or new mounting holes

-

With a 1" lift, you will have to modify the radiator flange a bit

to install the bracket

-

The radiator (and fan shroud) are attached to the body, the engine (and

fan) to the frame

-

Stock front bumper drop bracket and hardware (if needed):

-

Will raise stock bumper to original height as bumper will no longer fit

with body lift

- On 4Runners, the rear bumper is attached to the underside of the body

-

Will raise stock bumper to original height as bumper will no longer fit

with body lift

-

Stock rear bumper relocation hardware (Tacoma pickups)

- Hardware kit allows existing rear bumper brackets to be modified to match body lifts from 1"-3" and re-use the stock bumper bracket bolts.

-

A bracket for raising Toyota

A/T transfer case lever for 2" - 3" lifts is now

available:

- Bracket includes mounting hardware.

-

A steering shaft extension

for Toyota rack and pinion as well as recirculating ball steering box

steering:

- Extension bolts on to the stock rag joint and extends the shaft 1" or more

-

Bed Spacers

- For certain vehicles, there are places where the bed or body is supported by contact with the frame. While the body lift blocks and longer bolts will properly support the bed or body, for added load capacity, a separate bed spacer can be bolted or welded to the frame to provide a contact point.

-

If you want to "roll your own", click here for a VRML model of a

body lift block

- A proper body lift block should be uncompressible, there should be minimal play between the bolt and block to prevent it from racking

-

If interested in "rolling your own", I'd be more than happy

to supply you with a suitable quantity of material:

- 2" UHMW rod at $2.00/inch, 2.5" at $3.00/inch and $1.00 per cut on either item

-

1/2" - 3" lift w/ or w/o hardware:

One thing about many of the commercially available body lift kits is that they are an all-in-one package, one size fits all:

- If you want just the blocks, you have to buy the whole kit and throw away the parts you don't need.

-

If you want shorter blocks, you cut the taller blocks in two and throw

away the parts you don't need.

- Much of the hardware supplied is specific to the amount of lift in the blocks, so it can't be re-used.

- Bolts only have thread on the lower inch or so of the bolt, so if its shortened more than this, its no longer a bolt, its just a round rod with a hex head on top.

So, 4Crawler Offroad has chosen to supply a body lift in an "ala carte" form, e.g. you want blocks, you order the blocks; you want bolts, you order the bolts, etc. Here is a list of some common combinations of parts that are typically ordered.

[Return to the top of this page]Poly Urethane Body Mount Bushings:

Check out this photo album for more details on our polyurethane body mounts. Click on any of the image thumbnails to see a larger photo plus information.

While not required, it is a good idea to check the condition of the stock rubber body mount bushings and if cracked or worn out, change them to polyurethane (PU). PU will withstand the added strain of the taller body lift, and it actually transmits less noise and vibration from the frame to the body than rubber.

If planning to install a body lift kit on your vehicle, it is a good idea to inspect your original body mount bushings to see what condition then are in. Look for any deep cracking or tears in the rubber bushings. And with the one piece bushings, look for separation of the rubber from the surrounding steel bracket or places where the bushings have collapsed and are allowing the body to rest directly on the frame bracket (usually you'll hear squeaking or rattling noises if this happens). If you have any doubt about the condition of the original rubber body mount bushings, there is no better time than when installing a body lift to swap out those bushings, since you can easily swap out the bushings prior to putting in the body lift blocks.

Speaking of squeaking, there's a common misconception that poly urethane body mount bushings are prone to squeaking. While it is true that poly urethane suspension bushings are prone to squeaking, realize the squeaking happens when there's something moving against the poly bushing. Imagine a spring shackle or control arm bushing as the suspension cycles up and down. The bushing will be rotating against whatever is touching it and that's where the squeaking comes from. Common solutions are to apply lubricant to the poly or use a black, graphite loaded urethane material. On the other hand, a poly body mount bushing is a different application. The body sits on the bushing and the bushing captures the body mount bracket and all that is held together with a bolt. For squeaks to happen, something has to move across the poly bushing. If your body is sliding around atop those bushings, something is seriously wrong, i.e. body mount bolts are loose or missing. If that is the case, fix the problem and the squeaks should go away. Long story short, no need for additional lubrication with poly body mount bushigs.

Especially on the newer model full bodied vehicles, the trend is the the mfg. to install taller, softer rubber bushings for a quieter ride on the road. However, in off-road use, those large squishy factory bushings can allow excessive body movement relative to the frame. If you have aftermarket bumpers, rock sliders or other trail protection (like a roll cage) install, the body may move enough to make contact with that trail armor and cause noise. Also, those soft rubber bushings are more prone to tearing when subjected to the extreme stresses of off-road driving. In these cases, the firmer polyurethane bushings are a good upgrade.

What makes the bushing kits offered by 4Crawler Offroad different than those from other companies?

- We offer kits for many vehicles for which there are no aftermarket kits available.

- We offer any combination of bushing components, if you need 1 or 2 bushings or need to add or subtract bushings from an existing kit, no problem.

- We hand inspect and test-assemble each bushing kit in most cases. Amazing as it seems, we find that at least 25% of the boxes of supposedly complete bushing kits we open are missing parts. So we try and make sure each kit is complete and order extra parts from the bushing mfg. to make up any shortages before the bushing kit gets to you.

- We custom drill all the bushing washers to fit the size hardware you'll be using with the bushings. Most aftermarket bushing kits will not work with stock size hardware, strange as it seems. So let us know what size/diameter hardware you plan to use with the bushings, and we'll do our best to accommodate that. There may be an additional charge to drill out these components, or you are welcome to perform that operation yourself.

Note that PU body mount bushings will likely look different than the OEM rubber bushings. There are several reasons for this, mostly to do with the different materials and molding operations. Rubber tends to be "squishier" than PU. As such, bushings are often designed to compress to a greater degree when made of rubber. So they will appear taller when uncompressed. Also, OEM rubber bushings are often molded with washers, sleeves and other metal parts bonded together inside in complex clamshell molds. This is how rubber has to be molded, it's put in a mold and then put under heat and pressure to allow the vulcanization process to occur. PU, on the other hand, is poured into an open mold as a liquid then heated in an oven to cure the polymer. PU molds have to allow for the cured part to be removed and thus they can't have the intricate ribbing and details like the rubber bushings. Case in point, look at the tire on your truck and compare that to a PU skateboard wheel. Also, with PU, the exact mechanical properties, like durometer, can be easily controlled by the polymer ingredients. With a rubber bushing, you have less control over the material properties and instead rely on the bushing shape to produce the desired bushing properties. That's why the rubber bushings often have complex ribbing and narrower/thicker sections to allow for the desired compression characteristics.